need hlp please

#1

Registered!!

Thread Starter

Join Date: Dec 2013

Posts: 6

Likes: 0

Received 0 Likes

on

0 Posts

Rep Power: 0

Idk if I posting in the right area or what im new so please bare wth me...I have a 98ek9 wth a 98 gsr swap...I was driving the other day and the car juss died? Went to start it and it cranks but wouldn't start, then it finally started after cranking it for a few times.this happened 3 times that day??? So I got it towed home read a few post and change out the coil and ignitor Rotor button, cap plugs wires and I have no spark!  I took off my dizzy from my other ek9 coupe and nothing so I bought a used dizzy from a running car and swapped out the guts and put them n my gsr distributor and I have spark one min and then the next min nothing I finally got the car running but runs like ****.if I hit the gas pedal it sounds like it want to rev up higher but it wants to shake Boggs and dies but if I let it idle it runs fine, so I went to start it 2hrs later and it did the same nasty bogging so my buddy pulled one of the plugs out and da car died and now it won't start again so im bk to square one and any hlp will b mush appreciate it, I getting grey hairs wth this **** and I cnt figure it out I dnt knw much about electrical

I took off my dizzy from my other ek9 coupe and nothing so I bought a used dizzy from a running car and swapped out the guts and put them n my gsr distributor and I have spark one min and then the next min nothing I finally got the car running but runs like ****.if I hit the gas pedal it sounds like it want to rev up higher but it wants to shake Boggs and dies but if I let it idle it runs fine, so I went to start it 2hrs later and it did the same nasty bogging so my buddy pulled one of the plugs out and da car died and now it won't start again so im bk to square one and any hlp will b mush appreciate it, I getting grey hairs wth this **** and I cnt figure it out I dnt knw much about electrical

I took off my dizzy from my other ek9 coupe and nothing so I bought a used dizzy from a running car and swapped out the guts and put them n my gsr distributor and I have spark one min and then the next min nothing I finally got the car running but runs like ****.if I hit the gas pedal it sounds like it want to rev up higher but it wants to shake Boggs and dies but if I let it idle it runs fine, so I went to start it 2hrs later and it did the same nasty bogging so my buddy pulled one of the plugs out and da car died and now it won't start again so im bk to square one and any hlp will b mush appreciate it, I getting grey hairs wth this **** and I cnt figure it out I dnt knw much about electrical

I took off my dizzy from my other ek9 coupe and nothing so I bought a used dizzy from a running car and swapped out the guts and put them n my gsr distributor and I have spark one min and then the next min nothing I finally got the car running but runs like ****.if I hit the gas pedal it sounds like it want to rev up higher but it wants to shake Boggs and dies but if I let it idle it runs fine, so I went to start it 2hrs later and it did the same nasty bogging so my buddy pulled one of the plugs out and da car died and now it won't start again so im bk to square one and any hlp will b mush appreciate it, I getting grey hairs wth this **** and I cnt figure it out I dnt knw much about electrical

#3

Registered!!

Thread Starter

Join Date: Dec 2013

Posts: 6

Likes: 0

Received 0 Likes

on

0 Posts

Rep Power: 0

Re: need hlp please

Yes obd1i dnt have a stock ecu to check if I have any cel, ecu was chipped already when I got the car and its been fine till the other week.I did have a shop checked it out and they cut two wires from my ecu harness so I dnt throw a cel??? I really appreciate ur hlp u juss cnt find good hlp these days im lost I've tried Everest I can imagine, oh and I finally got it running for a short period of time but it was running really rough if I hit the gas it shakes and wants to die but if I let it idle it was fine turned da car juss to make sure it will start again and nothing

#4

SOHC Enthusiast

Re: need hlp please

Yes obd1i dnt have a stock ecu to check if I have any cel, ecu was chipped already when I got the car and its been fine till the other week.I did have a shop checked it out and they cut two wires from my ecu harness so I dnt throw a cel??? I really appreciate ur hlp u juss cnt find good hlp these days im lost I've tried Everest I can imagine, oh and I finally got it running for a short period of time but it was running really rough if I hit the gas it shakes and wants to die but if I let it idle it was fine turned da car juss to make sure it will start again and nothing

....if everything is as it should, Then try the retard and advance of the dizzy....there are 3 12mm bolts if I'm not mistaken....just loosen them a bit, and turn towards the radiator to retard....towards the back of engine bay to advance. (Again if I'm not mistaken)

If it runs any better after to retard/advance timing then i would say without a doubt your belt jumped....Try a full retard...then see how it runs....then a full advance..see how it runs....if either one seem much better....then start moving it little by little till you get it where you want....then if your capable....re-do the timing belt if necessary.

But pleaseeeeeeeee swap & or check all your internals on your dizzy...make sure #1 its the right dizzy....then put the right internals in there...

Also check your pins on your ECU & Dizzy connector...make sure the wires are all in place...make sure there no stragglers...all nice and tight....it may just be an intermittent interruption of not getting the signal from the ecu to the dizzy

Last edited by SeAmUs_MaCk; 05-14-2014 at 01:21 PM. Reason: Forgot information

#5

Registered!!

Join Date: Jul 2009

Location: Wasaga Beach

Posts: 282

Likes: 0

Received 0 Likes

on

0 Posts

Rep Power: 0

Re: need hlp please

Also make sure you have all the wires correctly connected on the dizzy. maybe there is a firing mis order. I had a similar issue on a d16 and it was he cam sensor in the dizzy screwing up.

#6

Registered!!

Thread Starter

Join Date: Dec 2013

Posts: 6

Likes: 0

Received 0 Likes

on

0 Posts

Rep Power: 0

Re: need hlp please

The dizzy internals came from an ls dizzy and swapped into a gsr dizzy I have tried retard and adv the dizzy and nothing changes but when I give it gas sound like and feel like a misfire.

#7

SOHC Enthusiast

Re: need hlp please

CKP Sensor "Crank Position Sensor" also known as RPM Sensor. The CKP sensor is commonly located on the side of the head, inside the Distributor. Not to be confused with the TDC or CYP sensor that is also located in the distributor, or in its own housing driven by the exhaust camshaft. On V6 Engines the CKP can be found behind the camshaft pulley. The CKP is a magnetic pulse generator type of sensor. The ECU monitors the CKP to determine crankshaft position and RPM and is the primary sensor for the ignition system.

Below is a picture of an CKP CYP TDC sensor in a B16A2 Distributor. The yellow arrow is pointing to the CKP magnetic pickup and the pulsar

Aim:

Diagnose code 4.

Required:

Basic Testing

- Digital Multi Meter

- Tachometer ( vehicle tacho can be used )

- paper clip

Advanced Testing

- all the above

- oscilloscope or wave form viewer

Symptoms

For a faulty CKP sensor to trigger code 4, you will more than likely get the engine light come on and the car will go into limp mode, Limp mode is a preset fuel and ignition map running on a backup processor in the ECU. Limited to about 3500rpm and a rich mixture to protect the engine. The engine will run, but not the best. Common cause for code 4 is a damaged CKP from distributor bearing failure or open circuit in the sensor or wiring back to the ECU.

Basic Test

- Perform a Visual inspection and make sure the CKP sensor is connected, lisen for metallic sounds from the distributor. Save yourself allot of time, If you have a very noisy distributor with lots of grinding metallic sounds, replace your distributor.

CKP Sensor Pin out Picture

OBDO

OBDI

wire side of connector

( note, unfortunately CKP sensors come in a variety of different connectors for different types for Honda's. In this DIY, I have just covered the basic all in one distributor. If you have a 4 wire distributor, Legend ect, reply to this thread and Iím sure some one will be able to help. )

**** Resistance Test **** Set the multi meter to ohms ( 2k scale )

Unplug the CKP sensor, connect your Red multi meter lead to the CKPP. Connect your Black multi meter lead to the CKPG.

CKPP

OBDO = Pin 2

OBDI = Pin 5

OBDII = Pin 5

CKPG

OBDO = Pin 1

OBDI = Pin 6

OBDII = Pin 6

their are two types of sensors.

350ohm to 750ohm ( most Honda's are 350ohm to 750ohm)

or

700ohm to 1300 ohm

If your CKP is not with in spec replace it ( or the distributor ). To be safe, consult the workshop manual for the actual specs for you CKP.

**** Voltage Test ****

Set your multi meter to AC Volts ( 20v scale )

Step 1

Check the CKP sensor for its output Voltage to the ECU, Connect the Black Lead from your multi meter to the chassis for a good ground. Back probe* the CKPP ( Crankshaft position Sensor Power) with the Red lead while the sensor is connected.

OBDO = Pin 2

OBDI = Pin 5

OBDII = Pin 5

KOER* at idle ( 800RPM ) you should get about 2.5 to 3vac

KOER* at 2500RPM you should get about 7.5 to 8vac

You can also test the CKP signal at the ECU connectors

OBDO = C1

OBDI = B15

OBDIIa = C2

OBDIIb = C8

If you do not get a signal, replace the CKP ( distributor )

**** Frequency Test ****

Set your multi meter to Hz scale

Step 1

Check the CKP sensor for its output frequency to the ECU, Connect the Black Lead from your multi meter to the chassis for a good ground. Back probe* the CKPP ( Crankshaft position Sensor Power) with the Red lead while the sensor is connected.

OBDO = Pin 2

OBDI = Pin 5

OBDII = Pin 5

KOER* at idle ( 800RPM ) you should get about 160khz

KOER* at 2500RPM you should get about 490khz

You can also test the CKP signal at the ECU connectors

OBDO = C1

OBDI = B15

OBDIIa = C2

OBDIIb = C8

If you do not get a signal, replace the CKP ( distributor )

**** Continuity Test ****

Set your multi meter to continuity. This setting is mostly a picture if a sound .))) when you touch the Red and Black leads together on your meter it should beep.

STEP 1

make sure the Ignition is off and unplug the CKP Connector and the ECU Connectors for this test

Continuity test between CKPP and ECU, Connect your Red multi meter lead on the CKPP, Back probe* the Black multi meter lead on the ECU Pin below that suits your car.

OBDO = C1

OBDI = B15

OBDIIa = C2

OBDIIb = C8

your multi meter should beep and read short or 000.0ohms. Place the black multi meter lead on a good ground source. You should not get beeping, this is testing for short to ground.

STEP 2

make sure the Ignition is off and unplug the CKP Connector and the ECU Connectors for this test

Continuity test between CKPG and ECU, Connect your Red multi meter lead on the CKPG, Back probe* the Black multi meter lead on the ECU Pin below that suits your car.

OBDO = C2

OBDI = B16

OBDIIa = C12

OBDIIb = C9

your multi meter should beep and read short or 000.0ohms. Place the black multi meter lead on a good ground source. You should not get beeping, this is testing for short to ground.

Advanced Test

You may pass all the above test with no problems at all. Unfortunately this does not mean all is well. You can have a sub code to the code.

example code 4 -1

code 4 is CKP

sub code 1 ( for example, ) is noisy CKP

You will not get sub codes from the SCS and MIL, you need the HDM or PGMFI Tester from the DLC port.

So in this advanced test, we are going to test the CKP with an Oscilloscope or Waveform Viewer to look at the signal generated from the CKP close up. The aim is to get a nice clean sine wave with out any glitches or drop outs.

Common causes of noisy sensors are rebuilt distributors. Once the bearing has failed and the pulsar has gone to town on the magnetic pickup and has damaged the pulsar and pickup assembly. Just changing the bearing in a dizzy rebuild sometimes doesnít cut it. Also cracks in the sensor housing is a bad thing.

Test Time

Connect the Black Lead from your waveform viewer to the chassis for a good ground. Back probe* the CKPP ( Crankshaft position Sensor Power) with the Red lead while the sensor is connected.

OBDO = Pin 2

OBDI = Pin 5

OBDII = Pin 5

KOER, you should get a pattern that looks abit like the pattern in the pic below.

you should not get a pattern with glitches or fuzz in the sinewave like in the pic below. if you do replace the sensor/distributor

* Notes

KOEO = Key On Engine Off

KOER = Key On Engine Running

Back probe the sensor, use a paperclip and push it into the connector then touch/clip your multi meter lead to the paper clip

Disclaimer: The following is provided as a GUIDE ONLY, and neither myself nor Ozhonda take any responsibility for the outcomes of someone else doing the following. You follow these steps at your own risk!

Last edited by SeAmUs_MaCk; 05-17-2014 at 08:49 AM.

#8

SOHC Enthusiast

Re: need hlp please

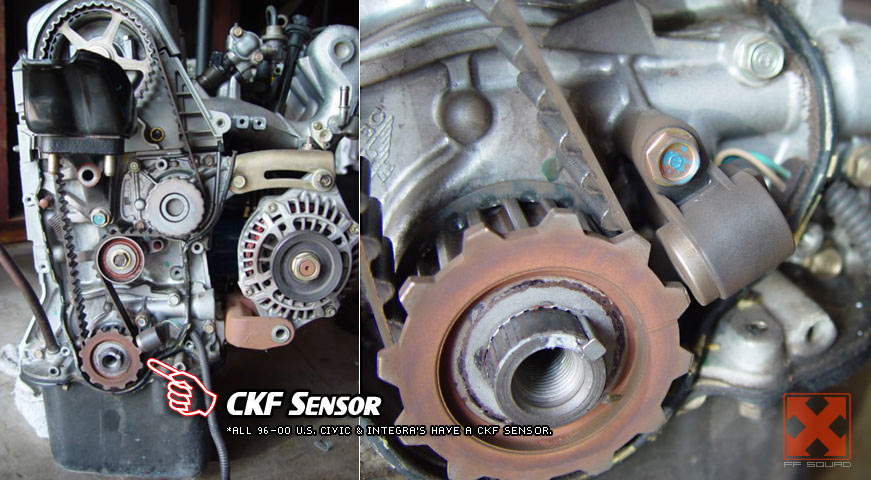

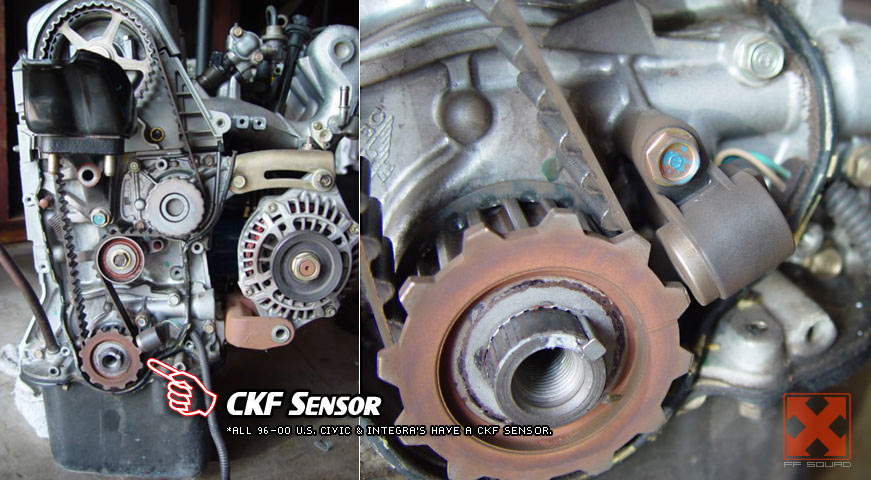

...I thought there was another down by the timing belt drive....but maybe thats only OBD-2 ....here's the diagram anyway

I know its from a SOHC but...maybe there is one down there on B series....like i said..not sure...but hopefully the last post I made will help you out...if not I guess research some more and find out....keep us posted...Now im curious as to why your not running correct.....

....It says right on the picture all 96-00 have one...so it's ONLY OBD-2....

....It says right on the picture all 96-00 have one...so it's ONLY OBD-2....

I know its from a SOHC but...maybe there is one down there on B series....like i said..not sure...but hopefully the last post I made will help you out...if not I guess research some more and find out....keep us posted...Now im curious as to why your not running correct.....

....It says right on the picture all 96-00 have one...so it's ONLY OBD-2....

....It says right on the picture all 96-00 have one...so it's ONLY OBD-2....

#9

Registered!!

Thread Starter

Join Date: Dec 2013

Posts: 6

Likes: 0

Received 0 Likes

on

0 Posts

Rep Power: 0

Re: need hlp please

Ty everyone for ur knowledge and hlp.im juss lost in all the electrical im not that advanced like others lol.I will give it a shot tomorrow morning and see if I can get lucky enough to find my source headache. Once again thank you everyone.

#10

Registered!!

Join Date: Jul 2009

Location: Wasaga Beach

Posts: 282

Likes: 0

Received 0 Likes

on

0 Posts

Rep Power: 0

Re: need hlp please

The CKF Crank position sensor is the one by the pulley on the bottom of the block. That is only required for OBD2. And running with out it will not do anything except throw a code. ( I know this because I ran a OBD1 motor with a OBD2 ECU for over a year)

The one in the Dizzy is a Cam Position sensor. And that sounds to be the issue. Or the Plug wires for the spark plugs are not correctly connected.

The one in the Dizzy is a Cam Position sensor. And that sounds to be the issue. Or the Plug wires for the spark plugs are not correctly connected.

Thread

Thread Starter

Honda Civic Forum

Replies

Last Post

jtb082013

Mechanical Problems/Vehicle Issues and Fix-it Forum

1

05-19-2014 07:11 AM